The Crucial Role of Fire-Rated Sheetrock in Home Safety

- Justin Birtwell

- Nov 19, 2025

- 5 min read

Updated: Jan 24

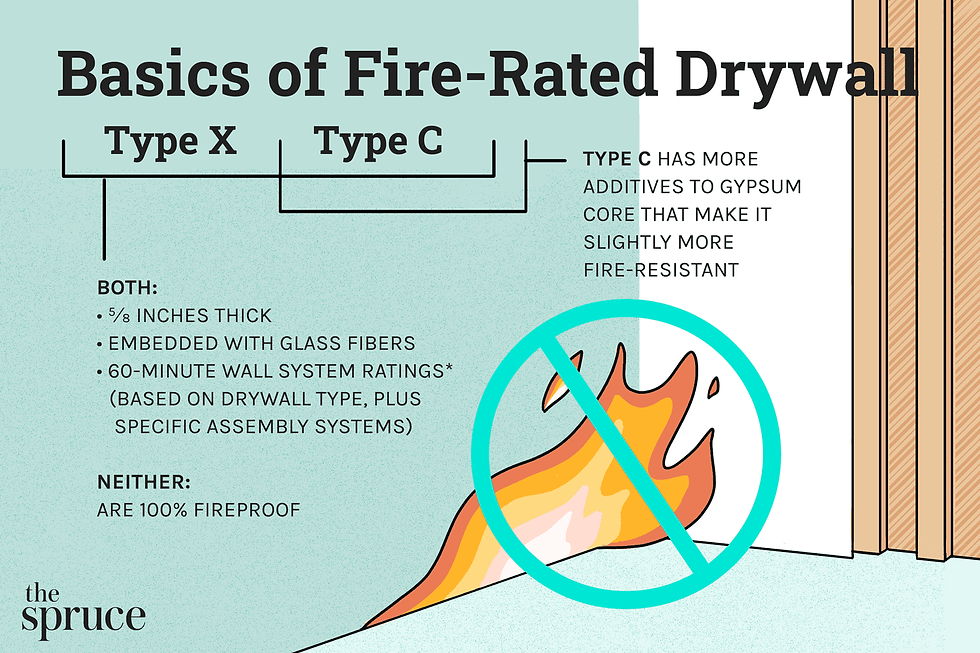

In an era where home safety is paramount, one often-overlooked hero in protecting lives and property is fire-rated sheetrock, also known as fire-rated drywall or Type X/Type C gypsum board. This specialized building material isn't just another layer on your walls—it's a critical barrier that can mean the difference between a contained incident and a devastating blaze. Fires can erupt unexpectedly from electrical faults, cooking mishaps, or even external sources, spreading rapidly through a home. Fire-rated sheetrock is engineered to resist burning longer than standard drywall, providing precious extra time for evacuation and firefighting efforts. According to building experts, its primary purpose is to delay the spread of fire, extending escape time in residential settings where quick exits are feasible but still vital. In this blog, we'll explore why fire-rated sheetrock is essential, the key areas in your home that require it, how to spot it through simple observations, and practical steps to boost fire resistance if it's absent.

Why Fire-Rated Sheetrock Matters

Fire-rated sheetrock plays a pivotal role in modern home construction by enhancing overall fire safety. Standard drywall, made from gypsum plaster sandwiched between paper layers, offers about 30 minutes of fire resistance before degrading. In contrast, fire-rated versions incorporate glass fibers and other additives into the gypsum core, allowing them to withstand flames for up to an hour or more in tested wall assemblies. This extension isn't about stopping fire entirely—no material is truly fireproof—but about slowing its progression. For instance, Type X drywall, the most common type, boosts a wall's rating to at least one hour, giving occupants time to escape and reducing property damage.

The importance extends beyond immediate safety. Many building codes, such as the International Residential Code (IRC), mandate its use in high-risk zones to comply with safety standards. Installing it can lower insurance premiums, as insurers recognize the reduced risk. In multi-family homes, it prevents fire from jumping between units, protecting neighbors and minimizing communal losses. Moreover, it offers secondary benefits like better sound insulation and structural strength, making homes quieter and more durable. While the upfront cost is higher—around 20-30% more than regular drywall—the long-term savings in potential fire-related repairs and lives saved make it invaluable. Type C variants go further, with additional vermiculite for up to four hours of resistance in some configurations, ideal for stricter commercial or high-risk residential applications.

Ultimately, fire-rated sheetrock isn't a luxury; it's a necessity in a world where home fires claim thousands of lives annually. By integrating it thoughtfully, homeowners can create safer environments without compromising aesthetics or budget.

Key Areas in the Home That Require Fire Retardation

Building codes dictate where fire-rated sheetrock is mandatory, focusing on areas prone to ignition or where fire could spread quickly to living spaces. The garage is a prime example: attached garages often store flammable materials like gasoline and tools, making them high-risk. The IRC requires 5/8-inch Type X on ceilings if there's habitable space above, and on walls shared with the house. This creates a firewall to contain fires originating from vehicles or chemicals.

Utility rooms housing furnaces, water heaters, or electrical panels also demand fire-rated drywall due to the presence of heat sources and potential gas leaks. In basements or areas below living spaces, ceilings must be protected to prevent upward fire spread. Kitchens and laundry rooms, with appliances and dryers, sometimes fall under local codes, especially in older homes retrofitted for safety. Walls separating garages from the home.

Garages need fire separation because they often store flammable materials like gasoline, vehicles, and chemicals, posing a high fire risk. A fire starting in the garage can spread rapidly to the home’s living spaces. Fire-rated materials, like 5/8-inch Type X drywall on walls and ceilings (if habitable space is above), create a barrier that slows fire spread, typically providing a one-hour resistance. This delay allows occupants time to evacuate and firefighters to respond, reducing property damage and saving lives. Local codes mandate these separations to ensure safety.

In multi-family dwellings like apartments or townhomes, separation walls between units require fire-rated assemblies to halt inter-unit spread. High-fire-hazard zones, such as those near wildlands, might extend requirements to all exterior walls and ceilings. Always check local codes, as variations exist—commercial buildings, hospitals, and high-rises have even stricter mandates.

TheSpruce.com: Basics of Fire-Rated Type X or C Drywall

Identifying Fire-Rated Sheetrock Through Observations

Spotting fire-rated sheetrock isn't always straightforward, especially post-installation, but several visual and physical cues can help. First, measure thickness: Standard drywall is typically 1/2-inch, while fire-rated is 5/8-inch for added density. Check exposed edges in attics, garages, or during renovations—if it's thicker, it's likely fire-rated.

Look for stamps or labels on the paper facing or edges. These often read "Type X," "Fire Rated," or include certifications like UL (Underwriters Laboratories) markings indicating fire resistance. The core might appear denser or have a grayish tint due to fiberglass additives, unlike the white of regular gypsum.

If painted over, you may need to inspect behind outlets or fixtures, or even cut a small section to verify thickness and composition. Professional inspectors use tools like borescopes for non-destructive checks. Remember, the rating applies to the entire wall system, including proper taping and sealing.

Recommendations to Improve Fire Rating If Missing

If inspections reveal absent fire-rated sheetrock, don't panic—several upgrades can enhance resistance. The gold standard is replacement: Install 5/8-inch Type X or C over existing walls, ensuring compliance with codes. For walls, add a layer without removing old material if space allows, achieving a one-hour rating. Seal all gaps with fire-rated tape and joint compound to prevent smoke and flame passage.

For less invasive options, apply intumescent coatings—special paints that expand when heated, forming an insulating char layer to boost ratings by 1-2 hours. These are ideal for retrofits and can be sprayed or rolled on. Gypsum veneer plaster over existing drywall is another enhancer, potentially meeting inspector approvals.

Holistic improvements include installing fire sprinklers, using fire-resistant insulation like mineral wool, and adding fire doors or blockers in stud cavities. Consult a professional for code adherence and testing—DIY errors could void protections. In shared walls, coordinate with neighbors for balanced upgrades.

Conclusion

Fire-rated sheetrock is a silent guardian in our homes, underscoring the importance of proactive safety measures. By understanding its role, required locations, identification methods, and upgrade options, homeowners can fortify their dwellings against fire's unpredictability. Whether building new or renovating, prioritize this material—it's an investment in peace of mind. Always involve experts and adhere to local codes for optimal results. Stay safe, and remember: prevention today saves lives tomorrow.

Maxim Home Inspections offers many types of inspections near Newtown CT (western Connecticut service area) including local home inspections, radon testing, mold inspections, termite inspections, , septic inspections and well inspections just to name a few. . If you'd like to have your home inspected you can get a quote an even schedule a home inspection with me you local home inspector.

Comments